|

|---|

Adhesives can generally be made into paint via the addition of pigments, and paste is no exception. However, while adhesives are generally designed to have a low water content, paints have no such requirement. In fact, paint can sometimes benefit from being highly dilute, as the goal is often to cover a maximum amount of area with a minimum amount of material. Starch pastes excel in this regard, and are improved greatly for this purpose by the addition of borax, which acts as a thickener, hardener, and preservative. Additionally, both starch and borax are emulsifiers, enabling the addition of linseed oil to a fundamentally water-based paint. This type of emulsion paint becomes dry to the touch rapidly by evaporation, forming a porous paint film which contains the oil as it cures. The water content of the paint also saturates the substrate, acting as a temporary barrier to prevent the loss of oil; in other words, the oil "floats" somewhat as the paint dries. The end result of these properties is an excellent paint for outdoor structures, which produces a completely waterproof coating using the absolute minimum amount of oil. It requires no solvents, catalysts, or other harmful materials, and can be cleaned up with ordinary soap and water.

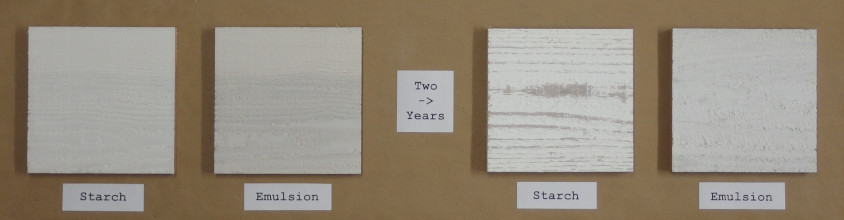

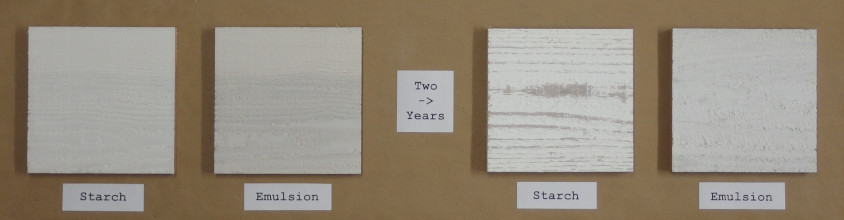

Unlike many of my more experimental projects, I have thoroughly tested this paint for the past two years, and it has performed well. Samples taken from a south-facing test fence can be seen at the top of the page, where two coats of paint were applied to red cedar pickets. While starch paint made without oil suprisingly survived (albeit with significant wear), the emulsion paint remained substantially unchanged, exhibiting only minor cracking in the softer areas of the wood. Accordingly, I would expect a useful life of 3-5 years under these conditions of direct exposure, which significantly outperforms the commercial water-based coatings that I have used previously for similar tasks. Furthermore, while the oil-free variation has poor weather resistance, it is usable as a mildew-proof (due to its borax content) paint for interior walls, where it easily replaces commercial latex paint at a much lower cost.

|

Making such a paint is simple, and the ingredients can be seen above in parts by weight. The most straightforward method is to simply add the starch and borax to the water, stir and heat the mixture until it thickens, then remove it from the heat and stir in the pigment. This method is suitable for small batches but involves quite a lot of stirring, so an easier method is to use five parts (or less) of the water to make a thick slurry with the solid ingredients, then boil the remainder of the water and pour it into this mixture. This instantly thickens the starch, and allows for the use of otherwise food-safe containers (e.g. cooking pots or kettles) to prepare the boiling water, which is useful when making large quantities of paint. In either case, the paint should be allowed to cool overnight before stirring in the oil. This allows the starch to thicken further and prevents the oil from separating out. Surprisingly, due to the high detergent power of borax, all stirring can be accomplished strictly by hand; however, using a drill mixer is still the much easier option, particularly when making large (multiple-gallon) batches of paint.

The ingredients of this formula are also highly adjustable, starting with the starch itself. While the above formula can be used with any starch (or flour containing gluten, which dissolves in borax solutions), the type of starch determines the useful range of its water content. Cereal starches (e.g. wheat, rice, or corn) typically tolerate 30 parts of water or less, while tuber starches (e.g. potato or cassava) will tolerate 30 parts of water or more. The relationship between water content and viscosity is highly non-linear for starches in general though, so test batches should always be made before committing to a particular recipe. Personally, I have found that all-purpose wheat flour is suitable for most tasks, and its low cost makes it my primary choice for painting large surfaces or structures.

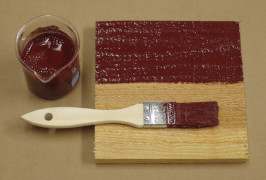

The pigment blend also has a significant effect on the qualities of the paint. While inert mineral pigments (such as iron, titanium, and chromium oxides, as well as the various ultramarines) should serve as the primary coloring material, I have found that up to 25% of this pigment (two parts by weight) can be replaced by zinc oxide, and up to an additional 25% replaced by clay, without significantly altering the color or covering power of the paint. Zinc oxide acts as a long-term hardener and preservative in emulsion paints, while clay reduces the settling and increases the brushability of starch paints in general. While dry kaolin (available from ceramic suppliers) is ideal due to its colorless nature, this can be substituted with ordinary stoneware or earthenware clay as long as it contains no coarse particles and is of a suitable color. Damp clay may even be used, provided it is pinched into thin pieces and blended thoroughly into the paint, and the additional water content taken into account. Finally, oil-free starch paint can also tolerate large amounts of fillers such as chalk or additional clay (replacing more of the pigment), which would otherwise be transparent in the presence of oil. None of the above modifications are strictly necessary, however; the paint seen below is made from only wheat flour, borax, and red iron oxide.

|

|---|

This paint replaces many of my previous materials in situations where a flat paint is needed for porous substrates, such as wood, plaster, or paper. It is far cheaper than my original oil paint for exterior work due to its lack of turpentine and lower oil content, and its rapid initial drying time avoids the typical hazards of wet paint. It is also cheaper and has a much longer shelf life than my casein paint for interior work, being stable in liquid form for over a year under ambient workshop conditions (30-90°F). Its adjustable viscosity also gives it potential as a shelf-stable craft or tempera paint, since it can easily be made thick enough to be stored in tubes or bottles without settling. Primarily however, this paint is most useful as a durable coating for large wooden structures exposed to the weather; practical tests in this regard are currently ongoing, and can be seen below. These structures were all coated with emulsion paint made using the default formula seen above, using wheat flour and a pigment blend consisting of 25% zinc oxide, 25% clay, and 50% either titanium or iron oxide for color. Time will ultimately determine the true lifespan of this paint in these applications, but at this point I am happy enough with the results that if needed, I would just give everything another coat.

|

|---|