The triode in the previous article began behaving erratically the next day, alternating between operating as a triode (with very poor transconductance) and operating as a thyratron, indicating the slow accumulation of gas in the tube. It appears that a getter is necessary, even for a thoroughly baked tube. Through experimentation, I discovered that my induction heater (a 1KW ZVS module from China) could manage to heat a small ring of 0.8mm titanium wire to an orange glow, so long as the ring was thoroughly spot welded shut to make a solid electrical connection. I immediately made another triode, with such a getter at the top of the tube. I also spot-welded 0.5mm nickel wire to the feedthroughs to improve the quality of mechanical connections to the leads, as well as to make the leads solderable. Nickel appears to spot weld readily to titanium, so long as the nickel wire is smaller than the titanium wire. Nickel is far more conductive than titanium, so if the two wires being joined are the same diameter, the nickel won't melt and the joint quality will be poor. Pictures can be seen below of the construction process.

I then attached the tube to the pump manifold. Once it had been evacuated to between 5 and 10 millitorr, I put the oven on top and began the following bakeout schedule:

At this point, I heated the getter with the pump running, to bake out any gases trapped in the titanium. I then forgot to light the filament and sealed the tube. Realizing my mistake, I lit the filament briefly before heating the getter again to absorb any stray gases in the tube. The tube appeared to perform well initially, and was tested over the course of the next three days. Each day the tube's emission would drop, but upon reheating the getter the original functionality would be restored. The amount of emission lost each day decreased over time, indicating that less and less gas was being evolved from the various components of the tube. Over time, I hope that it will get to the point where the sources of gas become so diminished that the getter will be able to handle them even while cold. I will continue testing the tube to see if this is the case. If it turns out that cold titanium is ineffective as a getter, future tubes may contain an extra lead for a titanium filament getter, to remove the need for the induction heater.

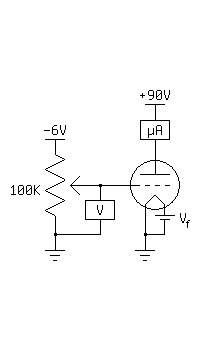

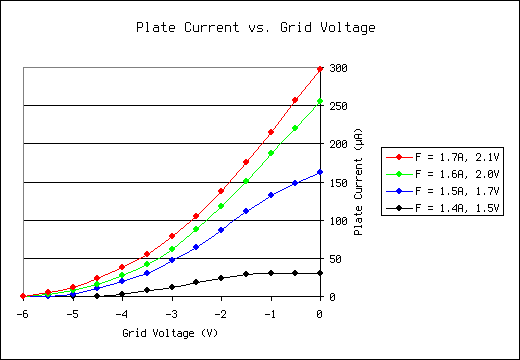

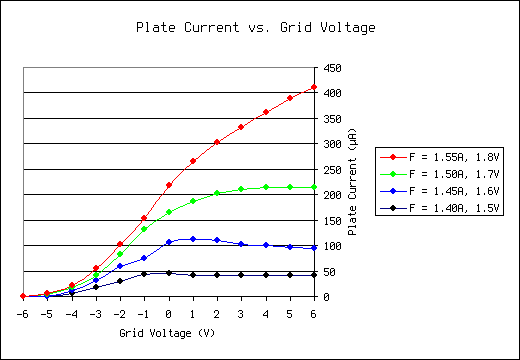

By the third day, I considered the tube to be a success and recorded its characteristics. The grid response curves at various filament settings can be seen below.

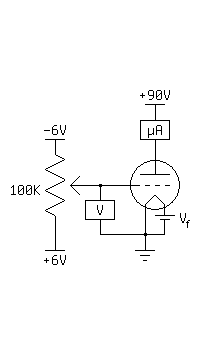

I noticed that at low filament power, the plate current would plateau before the grid reached 0V. I decided to investigate this further by modifying the grid bias circuit to be able to provide positive grid voltages. An interesting effect occurred.

It appears that this plateau exists for all values of filament power, but is pushed farther into the positive voltages as filament power increases. Even more interestingly, at very low filament power the plate current actually decreases as the grid voltage becomes more positive. I assume this is due to the tube being in saturation and the grid collecting electrons that would ordinarily have made it to the plate. If I had a third multimeter I could have measured the grid current and confirmed this, but it seems likely.

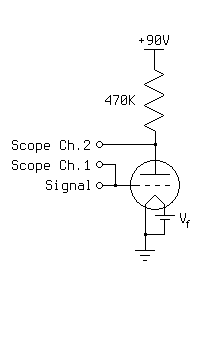

I then built an inverting amplifier. In the picture on the left, the input (bottom waveform) is a 10KHz 2V peak-to-peak sine wave, biased at -1V. The output (top waveform) is 20V peak-to-peak, indicating a voltage gain of 10. Like with the previous triode, gain began to drop off above 20KHz. However, this is most likely due to capacitive loading from the oscilloscope (25pF), which becomes an issue when measuring high-impedance high-frequency signals. This can be observed more clearly by switching the input signal to a square wave, the results of which can be seen in the picture on the right.

It is now apparent that not only can a triode be made with low-tech equipment, but also that it can be made to last by using a titanium getter. If this is successful in the long term, it will remove the need for amateurs to scavenge used getters from old vacuum tubes. Also, since titanium and nickel are compatible, such a titanium getter can be used in any type of tube construction. Nickel spot welds almost universally, so tubes with components made of different metals (such as stainless steel or tungsten) can use a titanium getter as well.