Objects are made from combinations of materials and coatings, and while materials determine the structural properties of an object, coatings determine the qualities of its surface. Surfaces serve as the interface between an object and the outside world, and as such must be compatible with both the underlying material and the surrounding environment. However, it is rare that a single coating can accomplish both tasks effectively, so often coatings are applied in layers, and this is where many mistakes can be made. Improperly layered surfaces can fail internally, wear poorly, or even detach from the material they are supposed to protect. After analyzing numerous examples of both successful and failed surfaces, I have developed the following summary:

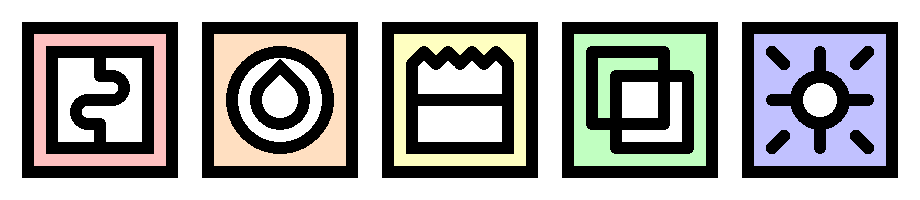

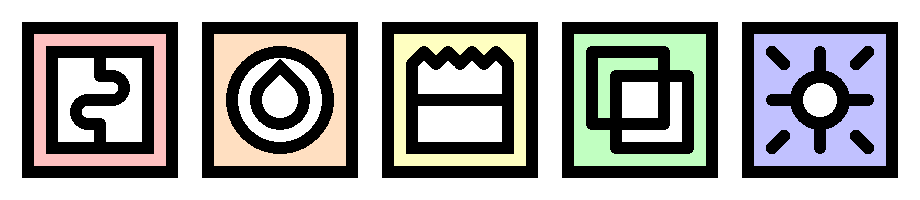

But what, specifically, does this mean? Which characteristics are being compared? Fundamentally, what is important are those characteristics which relate to the various common types of surface failure, with these being: adhesive, cohesive, mechanical, optical, and chemical. Each of these types of failure is associated with a certain physical property of the coatings which make up a surface. These properties are listed below, along with guidelines which prevent the type of failure in question:

Roughness is the most primitive property of a coating, and relates to the texture of the finished surface. It can either be due to particles contained within the coating, as in paints or putties, or created by the use of abrasives afterwards. Porosity is also an element of roughness, and can be thought of as amplifying it. Coatings should be applied in the order of rough to smooth, in order to avoid adhesive failure, since this allows each coating to fit into the voids within the underlying layer.

Solubility is a defining element of most coatings, which are often referred to as water-based or oil-based, with alcohol-based coatings being somewhere between these two. In more technical terms, this reflects the polarity of the solvent, and in practical terms the nature of the coating affects the adhesion between layers. Coatings should be applied in the order of water to oil to avoid cohesive failure, as water-based coatings generally wet poorly to existing oil layers, while the reverse is rarely an issue because no water is retained in the coating itself.

Flexibility is primarily a concern when considering the long-term stability of a surface. If a rigid coating is applied over something more flexible, it will eventually form cracks, which may lead to chipping and peeling. Coatings should be applied in the order of hard to soft to avoid this type of mechanical failure; this is one of the oldest rules of coatings, and is referred to as "fat over lean" in the context of oil painting. This principle is applicable to far more than coatings as well, and is something to consider when constructing any layered object.

Transparency should be considered where the look of an object is important; if an opaque layer such as paint is applied over something more transparent, surface wear will eventually break through and reveal the underlying material. Applying coatings in the order of opaque to transparent avoids this optical failure, by protecting layers of color or imagery with a transparent shield, which itself can be easily repaired. This can be seen everywhere from varnishing paintings to applying wax over automotive paint.

Durability is the final criteria, and is somewhat counter-intuitive in its application. I have found it beneficial to apply coatings in the order of strong to weak, in order to avoid chemical failure of the surface as a whole. Using a strong coating as the final layer tends to cause catastrophic peeling once this layer is breached, whereas protecting strong coatings with weaker ones provides an indicator of wear which does not compromise the integrity of the surface. For example, applying a layer of wax over a layer of varnish will cause the surface to become dull when the wax degrades, indicating the need for maintenance. Likewise with painting, using a layer of fugitive pigment over something more lightfast will allow the image to fade gracefully rather than disappearing outright.

If followed systematically, these guidelines should prevent any avoidable surface failures, albeit within the limitations of the coatings themselves. However, in some circumstances these rules may conflict, or a given rule may interfere with a design goal of the object as a whole; in this case, the guidelines provide a way to compare multiple risks of failure, in order to choose the one which is least detrimental to the overall project. Hopefully, these rules can serve as a roadmap for anyone interested in effectively preparing surfaces, and I intend to utilize and reference them from this point onward in projects of my own.