|

|---|

Although I have made a number of microphones in the past for transmitting speech, I have never made an earphone to receive it. This is primarily due to the fact that I considered speakers in general to be both simplified and optimized already, so I felt I had no need to investigate them further. However, upon further research, I found an interesting phenomenon which can be used to make what I believe is the simplest speaker possible.

Magnetostriction is a property of magnetic metals and alloys, by which they either expand or contract along the axis of an applied magnetic field. This change in length is roughly proportional to the strength of the field, up until the magnetic saturation of the material. Of the pure metals, iron exhibits this to a small extent, but nickel and cobalt are far superior, with nickel having the advantage of being commonly available as "Nickel 99" TIG welding rods. A coil of insulated wire wrapped around such a rod will convert an alternating current into powerful vibrations, and if the rod is then coupled to a thin rigid diaphragm, it will produce sound. Below is a working prototype:

|

|---|

The earphone at the top of the page operates on this same principle. At its center is a 1/8" nickel rod, which is peened over at the front to attach a thin (0.010") brass disc, and is threaded at the back to receive a tensioning nut. Surrounding it is a coil of six layers of 30-AWG wire, held on a loose-fitting bobbin so that the rod can move freely inside without disturbing the coil. The remainder of the earphone exists to house these components in a shape that is comfortable to both the hand and the ear.

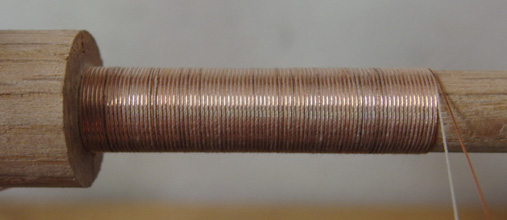

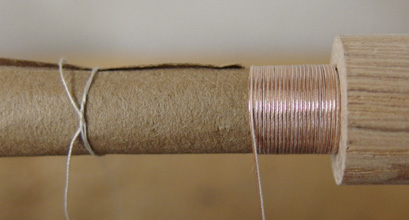

Since this is a fairly simple project mechanically, I also decided to take the time to experiment with a new style of coil winding. The coil of this earphone contains no magnet wire whatsoever; the copper is totally bare. Instead, the turns are insulated from each other by winding the copper alongside a cotton thread of equal diameter, and by inserting a layer of paper between each layer of wire. This requires some skill, but entirely eliminates the need for wire enamel as a material. The steps of this process can be seen below.

|

|---|

In terms of results, I was somewhat disappointed to find that my microphone lacks the necessary output power to produce audible speech from this earphone, which is something that warrants further experimentation. However, when powered by an ordinary headphone jack, the sound quality is surprisingly good. This is particularly interesting as this type of speaker is ideally powered by modulated DC rather than AC, but apparently the resulting distortion is either absent or inaudible. Due to this combination of simplicity and audio quality, I believe this type of speaker has significant potential, and I intend to experiment with making larger speakers for playing music. Specifically, I will experiment with adding some form of mechanical advantage to increase the diaphragm displacement, as I believe the magnetostrictive force of the nickel core is currently being under-utilized. For now, though, I have included a video of the earphone described above.