|

|---|

The cyanotype process is one of the simplest and safest methods for printing an image using light. If potassium ferricyanide and a light-sensitive ferric compound are dissolved in water and painted onto a porous substrate (usually watercolor paper), the surface will darken where light strikes it due to the production of potassium ferric ferrocyanide, which is a form of prussian blue. The remaining unreacted salts can then be washed away with water, and are generally environmentally benign. Despite this simplicity, in practice the process is often poorly understood and haphazardly executed, leading to a reputation of producing low quality and inconsistent prints. To resolve this, I decided to develop a simple and reliable method for making cyanotypes, in which all steps are fully understood and repeatable.

The first step was to design the sensitizer solution which produces the printed image. This contains the two ingredients mentioned above, and since potassium ferricyanide cannot reasonably be substituted for anything else, the only decision to make was on the specific light-sensitive ferric compound. Historically ferric ammonium citrate was used, but this is poorly-characterized (having no defined ratio of ingredients), unstable in solution, and retains moisture, forming a sticky layer on the coated surface. Instead, I decided to use ferric ammonium oxalate, which is a well-defined crystalline solid and which also has higher light-sensitivity.

The next step was to determine the ratio of these ingredients and their concentration in water. While the vast majority of cyanotype formulas specify a large excess of light-sensitive material, this is unnecessary, and leads to problems in the printed image such as solarization and bleeding. I found it more efficient and reasonable to have the two ingredients in equal molar concentrations, which I calculated to be 1.3 parts ferric ammonium oxalate for every part of potassium ferricyanide, by weight. In addition, I found it beneficial to include a small amount of oxalic acid in the solution, as most watercolor papers are alkaline-buffered. To determine the water content, I simply made solutions of increasing concentration until the prints no longer showed an improvement in intensity. Above a certain threshold the excess sensitizer crystallizes within the paper and is inactive, and I found that this generally happens at around 10% solids by weight. The resulting composition is as follows:

|

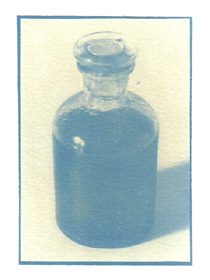

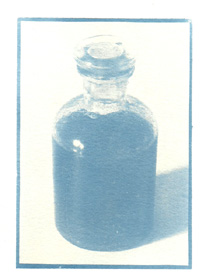

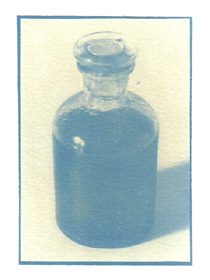

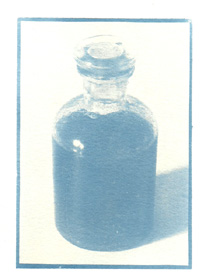

This solution can be prepared in bulk, and will keep for some time (at least a week) if stored in an amber bottle away from sunlight. In the long term it will degrade into prussian blue, but I found that this sinks to the bottom of the bottle, so the only problem is the loss of concentration. If brushed on thinly, I found that each milliliter of solution will cover around 100 square inches of watercolor paper, and if the sensitized paper is exposed to light as soon as it is dry to the touch, it produces a clean print with no blue pigment in the unexposed areas. High-quality negatives can be made with an ordinary printer using transparency film, and controlled exposures can be made with a 500W halogen lamp and a stopwatch. In general, five minutes of exposure at a distance of one foot from the lamp produces a decent image, and one such print can be seen at the top left of the page.

|

|---|

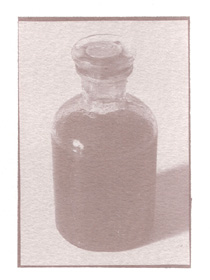

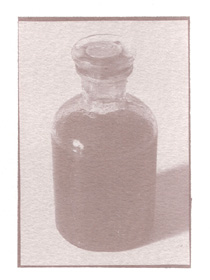

This type of print has one limitation, however; prussian blue is not entirely lightfast, and will fade if continuously exposed to sunlight. Fortunately, with a few additional steps, the pigment can be modified in-place to produce a more stable compound; namely, iron gall ink. This modification requires three dilute aqueous solutions which the print is first soaked in, then rinsed with water afterwards. These are depleted slowly and can be reused a number of times, typically by pouring a small amount into a tray for processing prints, then returning the contents of the tray to a storage bottle afterwards. They can be seen below, in the order in which they are used:

|

The developer bath has three purposes: first, it neutralizes any remaining alkali contained in the paper. Second, it dissolves any ferric hydroxide that may have formed due to the sensitizer reacting with the paper ingredients; without this step, toned prints become very dark and lose their contrast. Finally, it has an intensifying effect on the blue color of the print, and if the bluest possible print is desired, the process can be stopped here.

The bleach bath destroys the blue pigment by dissolving away the ferrocyanide ion, leaving behind a pale yellow image made of ferric hydroxide. This is generally too weak of an image to be clearly visible, but if a very light print is desired, this can be the final step.

The toner bath reacts with the ferric hydroxide from the previous step, forming a dark ink where the original image was printed. Different forms of tannic acid produce slightly different colors, but I achieved the best results by using oak gall powder, which has less of a tendency to stain the paper. At this point the image is stable, and should be able to withstand extended exposure to light. Each of these steps can be seen in order at the top of the page, to the right of the original print which was only rinsed with water.

This method is extremely cheap and simple to use, and with the improvements described above it produces consistent enough results for high-volume printing; in particular, I believe it has potential as an alternative to the printing press for the small-scale production of books, having a particular advantage if the book is to contain detailed images. In the future I intend to experiment with making glass negatives (both hand-written and photographic) for printing of this type, but for now I will continue experimenting with the cyanotype reaction, as it has a number of other uses which I would like to explore.

Interestingly, this cyanotype solution appears to be stable indefinitely. After years of storage in an amber bottle in a dark cabinet, it develops a thin layer of prussian blue on the inside of the glass and a small amount of sediment at the bottom of the bottle, but otherwise remains perfectly usable. The degradation process noted above appears to be self-limiting.

Also of note is the possibility of combining the initial rinse bath with the developer bath. If a dilute solution of oxalic acid (roughly 0.1% by weight) is used to rinse the exposed print, it develops no iron stains whatsoever. This then requires a second rinse in clean water and would be wasteful for large batches of prints, but may be useful for artistic work where the best results possible are desired.