If a tube has a base, it must also have a socket. Rather than make a custom socket for each tube, I developed a standard socket design to be used with any small tube having up to five pins. This implementation of the design uses a split brass collet for each pin location, held in place by a Delrin plug, which is designed to fit into a 3/4 inch hole in a wooden board. The back end of each collet has a small hole drilled in it axially, so that wires can be conveniently soldered in place.

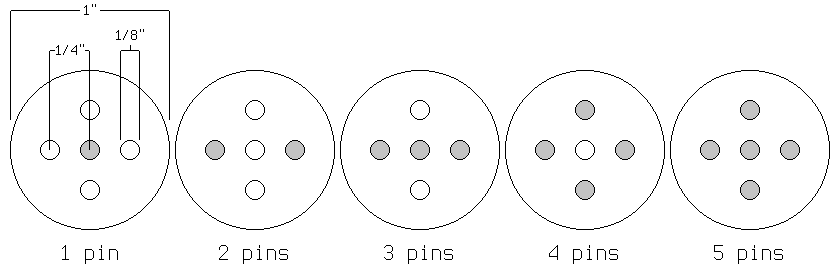

The key feature of this socket design is that a tube with any number of pins can have a symmetrical base, as the diagram below shows. The trade-off is that there is no keying mechanism to block a tube from being inserted in the wrong position. Future tubes and sockets will have an alignment mark, however, so that the tube position can be checked visually.

Assembly of the socket was straightforward, and the nickel plating on the diode's pins survived over 10 insertions without significant wear, confirming the viability of the plating process. The only issue I encountered was that the lead-free brass I used in the socket had the tendency to work-harden, making it difficult to achieve a good finish or close tolerances on such small parts. I will experiment with other materials to find something more suitable for this application.